Building a prototype of an electronics circuit is an essential skill for a beginner and experienced electronics hobbyists. If you are a complete beginner, you may not know where to start, and if you are already using a solderless breadboard and want to make your designs more permanent, this post will help guide you.

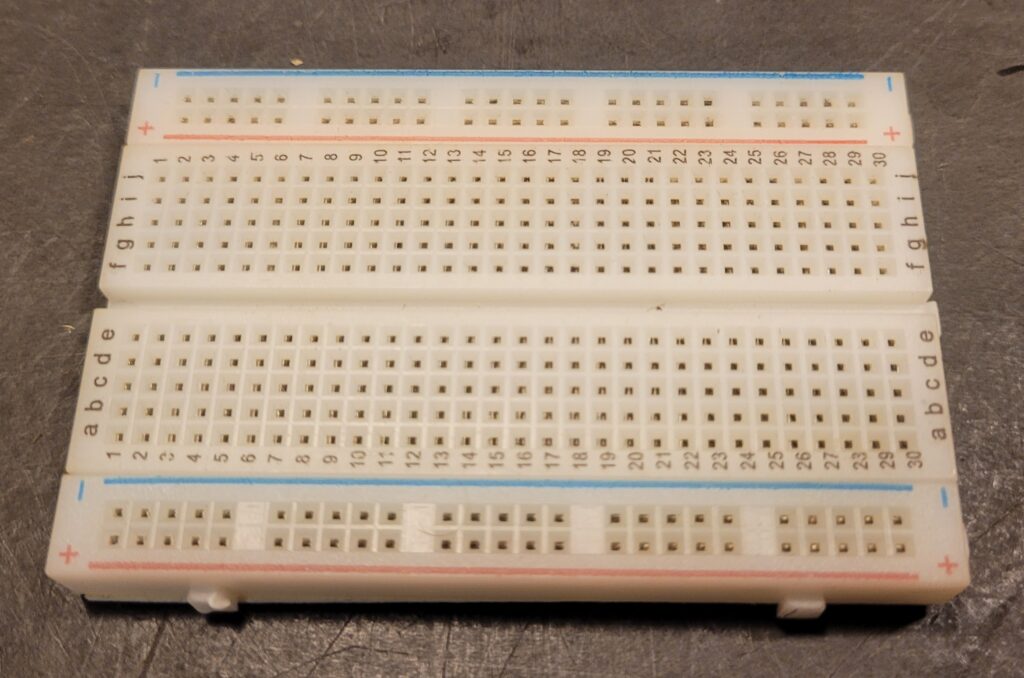

The purpose of a breadboard is to enable efficient prototyping of electrical circuits. A breadboard contains a certain arrangement of connection holes to facilitate the efficient manual arrangement of through-hole components on a board.

Below are some commonly asked questions about breadboards and their uses.

What are the two types of breadboards?

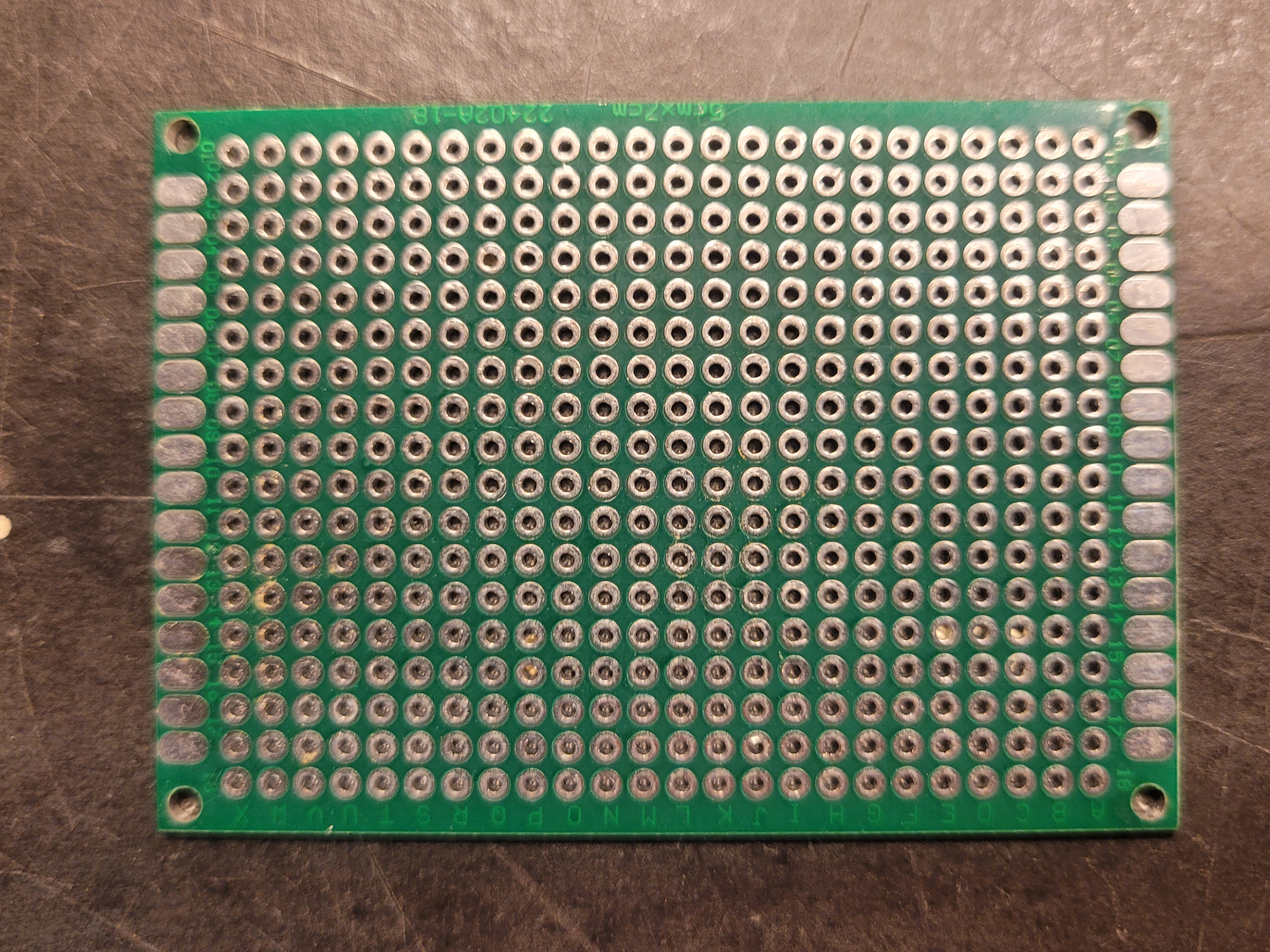

The two major types of breadboards are the solderless breadboard and a solder breadboard. The solderless breadboard provides a layout of connections for components without solder and the solder breadboard provides exposed metal contacts that can accept solder to create permanent connections to components.

Each of these two major types are available in several different sizes and layouts.

Both types of breadboards are used for prototyping electrical circuits without creating a custom printed circuit board, which can be a time consuming and expensive process. This makes both of these types of board good for hobbyists.

What is the purpose of a solderless breadboard?

The purpose of a solderless breadboard is to enable efficient prototyping of low power, low frequency electronic circuits using only temporary electrical connections.

Solderless breadboards are very common and convenient way to quickly build prototypes of your circuits. The boards have some great advantages, but also have many disadvantages.

Below are some advantages to a solderless breadboard:

- Support very fast assembly of prototypes of low power, low frequency circuits

- Can be reused to prototype many circuits

- Enables you to easily and rapidly test and modify a circuit

Below are some disadvantages to solderless breadboards:

- Not intended for high current, high voltage prototyping – It is much safer to use a permanent soldered prototype for high voltage projects. One reason for this is that if an extremely high current were to flow through the board it could melt it.

- Not useful for high frequency or low noise projects – Along with temporary nature of the connections provided in a solderless breadboard is that the connections are mechanically inconsistent and of somewhat low quality. This can introduce unwanted artifacts into circuits that become a problem for high frequency signals and low noise applications. However, this will most likely be irrelevant to you if you are a hobbyist, unless you are doing advanced projects.

- Not robust in environments with vibration such as for electromechanical projects – Due to the temporary nature of the connections, vibrations may cause components to make inconsistent contact with conductors in the breadboard resulting in unreliable operation of the circuit.

- The board is a fixed size

Bonus Tip

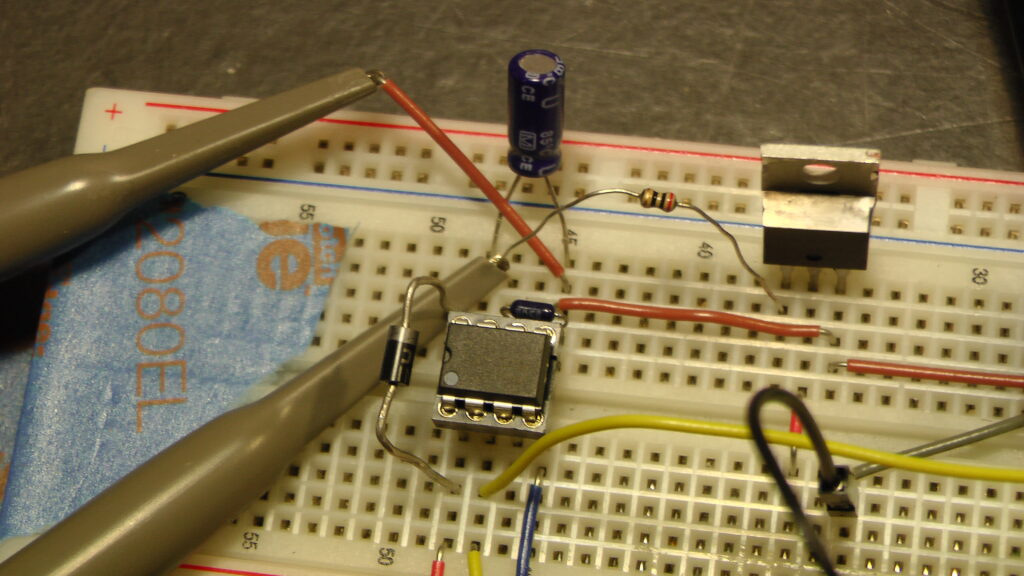

In addition to using your solderless breadboard to create a full prototype of a circuit, there is also another application for it. Have you ever ordered several or many of the same component and some of them do not work? I recently bought replacements for a component that had broken and some of the replacements were also broken.

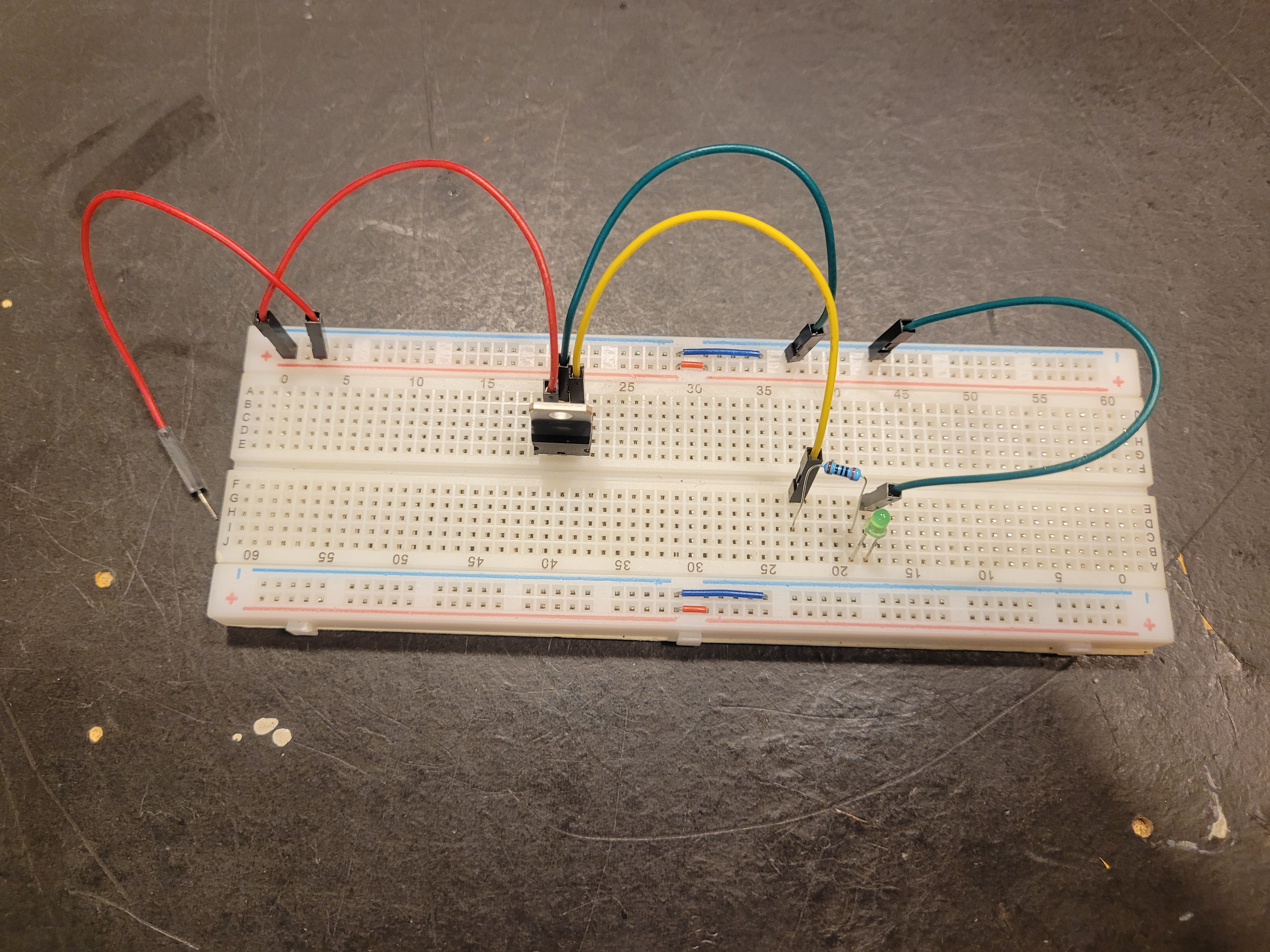

You can use the solderless breadboard to build a temporary test fixture for the component. I find the solderless breadboard to be a very convenient way to test a set of components and separate the components that are working properly from those that are not.

To do this, you first need to understand how the component is supposed to behave. You can then identify the power pins, inputs, and outputs of the component. Insert one of these components onto the board. Finally, connect the component up to a circuit that keeps it powered and provides an indication of how the component is functioning inside.

If the component is simple like an LED, you will be able to quickly check if the component is working if the LED emits light. However, in the case of something more complex, such as an IC (integrated circuit) chip, you will need to either provide some indicators such as LEDs to show the status of the outputs, or you could connect a volt meter or oscilloscope to an IC through connections on the breadboard to show the status of the component under test.

The benefit of testing components with a solderless protoboard is that you can quickly test a component, power off the board, insert the next component, power on the board again, check the status of the next component, and repeat.

What is the difference between solderless and solder breadboard?

The difference between a solderless and solder breadboard is that a solderless breadboard enables prototyping with entirely temporary (solderless) connections, and a solder breadboard supports building a more permanent prototype of a circuit using solder to form soldered connections.

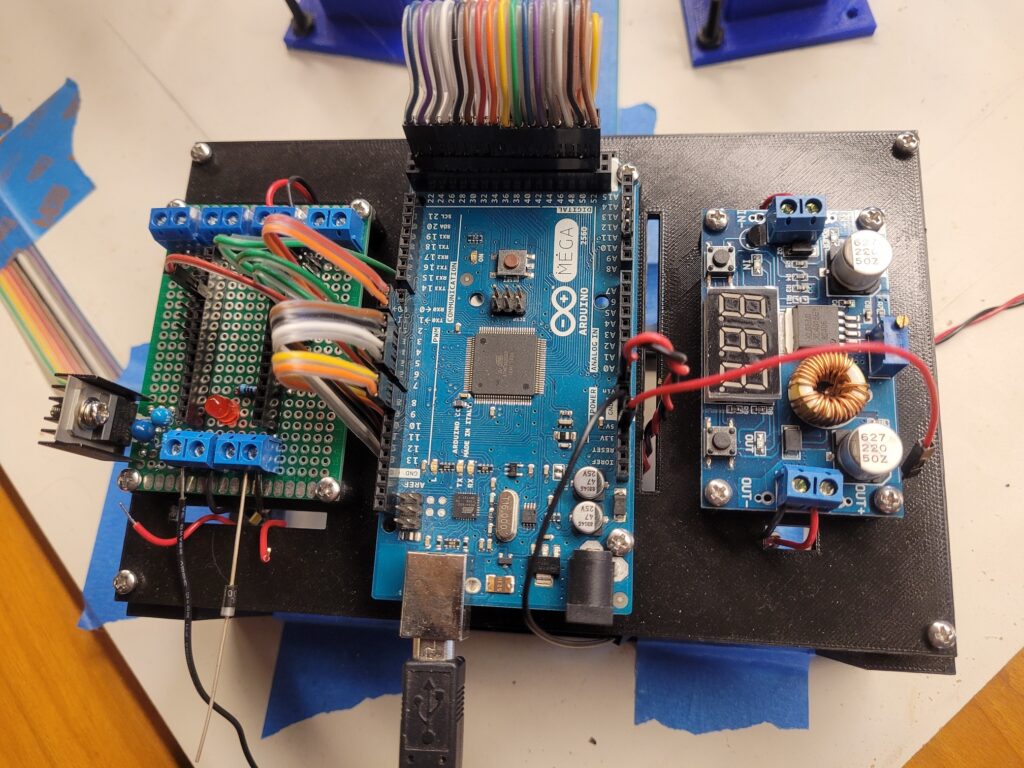

After you finish prototyping a circuit on a solderless breadboard, you may want to make your design more permanent. This can be achieved either by transferring your circuit over to a solder/soldered/solderable breadboard or designing and ordering a custom printed circuit board (PCB) with the necessary traces and connection holes and then soldering components to the custom board.

For many hobbyist the first option of using a soldered breadboard is sufficient.

The soldered breadboard provides several advantages over the solderless breadboard:

- Enables you to create a permanent circuit

- Supports high voltage applications

- Better for high frequency, low noise circuits

- Supports building of mechanically robust circuits that cannot easily fail in the presence of vibration

- You can cut a solderless breadboard to the desired size and 2 dimensional shape

- You can cut or drill a trace to split it into two separate conductors

- Boards can come with mounting holes for mounting to a project box or stand for example.

There are also some disadvantages to using a soldered breadboard instead of a solderless breadboard:

- Requires that you know how to solder

- Cannot be easily reused – You can unsolder the components from the board, but this will eventually wear out the traces and make parts of the board unusable.

- Requires more time to assemble a circuit than a solderless breadboard